Grade 100 Chain Slings: Strength, Safety, and Applications

Grade 100 Chain Slings: Holloway's Guide to Heavy Lifting | WLL & Applications

When it comes to heavy lifting, sometimes you need equipment that is as tough as the job demands. Our Holloway chain slings are designed for the most challenging applications and are built with high-grade alloy steel to deliver raw strength and durability. In this article, we’ll break down the basics of chain slings—from their design and load capacities to practical applications and maintenance. Whether working in an industrial setting or tackling a heavy-duty project, understanding these tools is crucial for safe and efficient lifting. Looking for alternative lifting solutions? Check out our guides on wire rope slings and synthetic slings for a broader perspective.

What Are Chain Slings?

Chain slings are heavy-duty lifting tools built to handle extreme loads. Our Holloway chain slings feature high-quality chains from Peerless Chain, which are known for their strength and reliability. The slings are paired with fittings from trusted brands like Cartec, Gunnebo, Pewag, and Yoke to ensure that every component meets industry standards.

While chain slings are built for raw power, alternatives like wire rope slings offer a balance of strength and flexibility, and synthetic slings deliver a gentler touch for delicate loads. However, our Holloway chain slings stand out as the optimal choice when it comes to the most demanding lifting tasks, especially those requiring high-temperature resistance and heavy load-bearing capacity.

How They’re Made and Types Available

Our Holloway chain slings are precision-engineered, combining Peerless Chain with industry-leading fittings for secure, dependable connections. They are designed to distribute loads evenly and maintain structural integrity under heavy conditions.

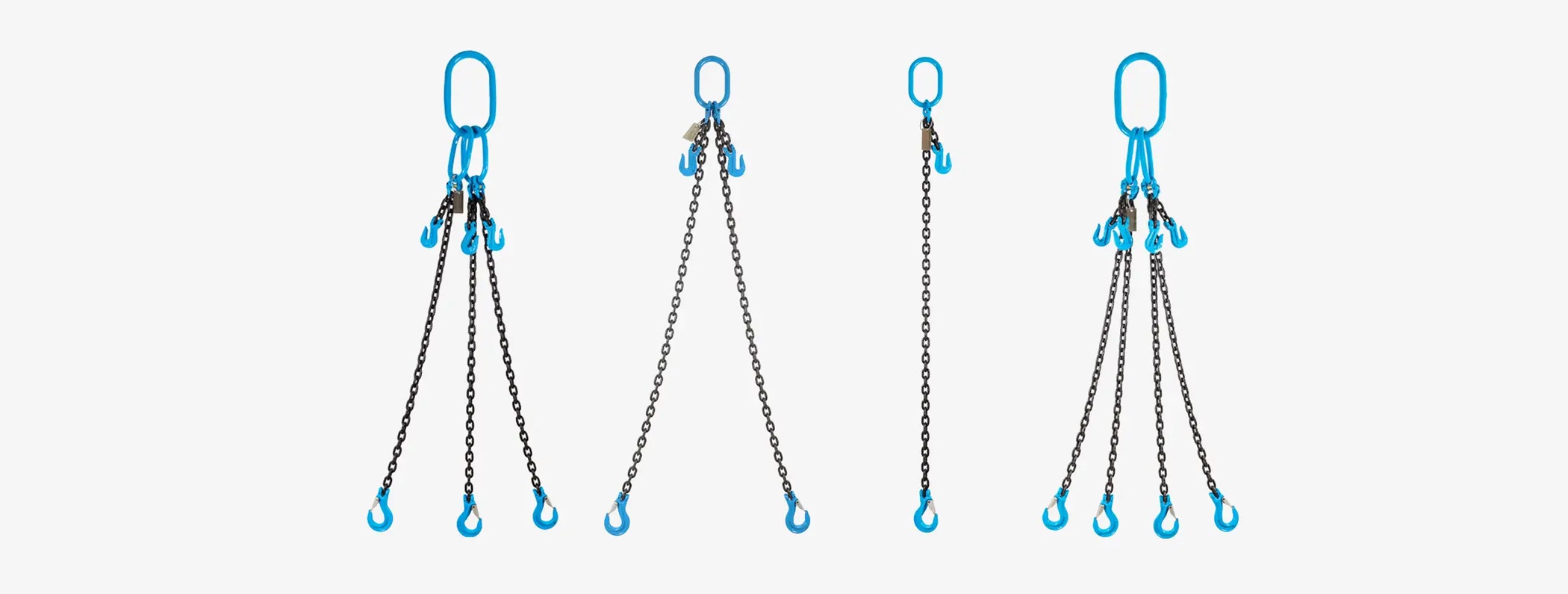

Available types include:

- Single–leg Holloway Chain Slings: Best for vertical lifts with a centrally aligned load. Their simple yet strong design makes them a choice for many industrial applications.

- Double–leg Holloway Chain Slings: Ideal for added stability and balanced load distribution, making them perfect for lifting wide or unevenly shaped loads.

- Four-Leg Holloway Chain Slings: Designed for lifting large and irregularly shaped loads, these slings provide maximum stability and weight distribution, reducing stress on individual legs and offering better control during lifts.

Many of our chain slings are made with Grade 100 materials, which offer increased tensile strength for critical applications where safety and performance must be maintained.

Load Capacities: What You Need to Know

A chain sling's safe working load limit (WLL) depends on factors such as chain size, grade, and construction. While Grade 80 chains are widely used, our Grade 100 Holloway chain slings are designed for higher lifting demands. Below are typical load capacities:

| Size (inches) | Single Leg WLL (lbs) – Grade 80 | Single Leg WLL (lbs) – Grade 100 |

|---|---|---|

| 3/8 | 7,100 | Up to 8,500 |

| 1/2 | 12,000 | Up to 14,400 |

| 5/8 | 18,100 | Up to 21,600 |

Grade 100 values are approximate. Exact ratings depend on the specific design and manufacturer specifications. Detailed product information, including components from Peerless Chain and high-quality fittings, provides precise load ratings for each model.

A 3/8-inch Grade 100 Holloway chain sling can handle significantly more weight than standard options, making it a practical choice for demanding lifting applications. Always select a sling that meets or exceeds the required load capacity with an appropriate safety margin.

Strengths and Limitations of Chain Slings

Understanding the benefits and drawbacks of chain slings helps select the right equipment for the job.

Advantages

- High Load Capacity: Holloway chain slings, especially those made from Grade 100 chain, are built to handle heavy loads. Peerless Chain components and top-tier fittings provide dependable lifting performance.

- Heat Resistance: Unlike synthetic or wire rope slings, chain slings perform well in high-temperature environments. They are commonly used in foundries, welding operations, and industrial applications where heat exposure is a factor.

- Long Service Life: With proper care, chain slings can be used for an extended period. Materials and fittings from Cartec, Gunnebo, Pewag, and Yoke contribute to their strength and usability over time.

Disadvantages

- Weight: Chain slings are heavier than synthetic alternatives, making them harder to transport and handle in certain situations.

- Less Flexibility: Unlike synthetic slings, chain slings do not conform as easily to irregularly shaped loads. This may limit their use in some applications.

- Noise During Use: The metal links of a chain sling generate more noise than synthetic or wire rope slings, which may be a factor in noise-sensitive environments.

Where They Shine: Applications in the Real World

Holloway chain slings are designed for demanding jobs where strength and toughness are key. Common applications include:

- Heavy Industrial Lifting: Foundries, shipyards, and large manufacturing plants rely on these slings to move heavy machinery, engine blocks, and steel components. Their ability to handle high temperatures makes them suitable for extreme conditions.

- Construction Sites: These slings are highly strong and are used for lifting steel beams, precast concrete, and other building materials. Grade 100 models and fittings from brands like Pewag and Yoke provide dependable performance.

- Mining and Quarry Operations: Built for harsh conditions, these slings handle abrasive and heavy loads, making them useful for moving materials in mines and quarries.

- Port Operations and Shipping: Designed for cargo handling, these slings support loading and unloading operations where strength and load control are critical.

Grade 100 Holloway chain slings are a strong choice for extreme loads or high-temperature conditions. Wire rope and synthetic slings may be worth considering if a lighter or more flexible option is needed.

How Chain Slings Compare

Choosing the right sling depends on the specific job requirements. Chain slings—especially Grade 100 models—handle heavy loads and high heat better than synthetic slings, which work well for delicate loads. Wire rope slings provide a balance of strength and flexibility.

A Grade 100 Holloway chain sling with Peerless Chain and high-quality fittings from Cartec, Gunnebo, Pewag, or Yoke is a solid option for extremely heavy loads or tough environments. Synthetic slings are often a better fit if minimizing surface damage is a priority. Wire rope slings offer an alternative for tasks requiring both strength and pliability.

These comparisons help in selecting the right lifting equipment and also allow for linking to other articles in this series.

Safety and Maintenance: Tips for Longevity

The lifespan and effectiveness of Holloway chain slings depend on proper care and handling. Key practices include:

- Regular Inspection: Before each use, check for bent or worn links and any signs of damage. Even a small defect can affect performance.

- Cleaning and Lubrication: Remove dirt and debris to prevent rust. Applying lubricant helps maintain smooth movement and prevents corrosion.

- Proper Storage: Keep slings in a dry, covered area away from harsh weather and chemicals to avoid premature wear.

- Even Load Distribution: Make sure weight is evenly distributed to prevent excessive stress on individual links.

- Training and Handling: Operators should be familiar with proper use to avoid mistakes that could damage the sling or affect safety.

Following these steps helps maintain chain slings' performance while reducing the wear risk over time.

Real-World Examples and Practical Insights

Lifting a heavy steel beam on a construction site requires a strong, well-built chain sling. A single-leg Grade 100 Holloway chain sling with Peerless Chain and fittings from trusted brands handles the task effectively. In another scenario, a foundry may use a double-leg configuration to lift machinery safely by distributing the weight more evenly.

In mining, where rough conditions and abrasive materials put equipment to the test, these chain slings deliver reliable lifting power. These examples highlight why they are widely used in industries where load handling is a daily challenge.

Wrap-Up

Holloway chain slings are designed for demanding lifting jobs. Made with Peerless Chain and high-quality fittings from Cartec, Gunnebo, Pewag, and Yoke, these Grade 100 slings provide strength and heat resistance. Commonly used in construction, shipyards, mining, and port operations, they are a dependable choice for heavy lifting tasks.

Selecting the right lifting solution depends on job requirements. Grade 100 Holloway chain slings work well for extreme loads and tough environments, while wire rope and synthetic slings offer alternatives for different needs.

Regular inspections, cleaning, proper storage, and correct handling all help extend the life of chain slings and keep lifting operations running smoothly.

For more insights on lifting solutions, check out our guides on wire rope and synthetic slings. Each article provides helpful details for choosing the best equipment for the job.