Wire Rope Slings: Tough Lifting, Smart Solutions

Wire rope slings are key in lifting operations across construction, shipping, and logging industries. Made by flemishing steel wires together, these lifting wire slings provide strength and adaptability, making them helpful in handling heavy loads. Whether moving steel beams on a job site or lifting logs in forestry work, wire rope slings are a trusted tool for lifting professionals. This guide will look at how steel wire rope slings are made, their load capacities, and the benefits and limitations they bring to different tasks. Our chain and synthetic slings guide offers valid comparisons if you're considering alternatives.

What Are Wire Rope Slings?

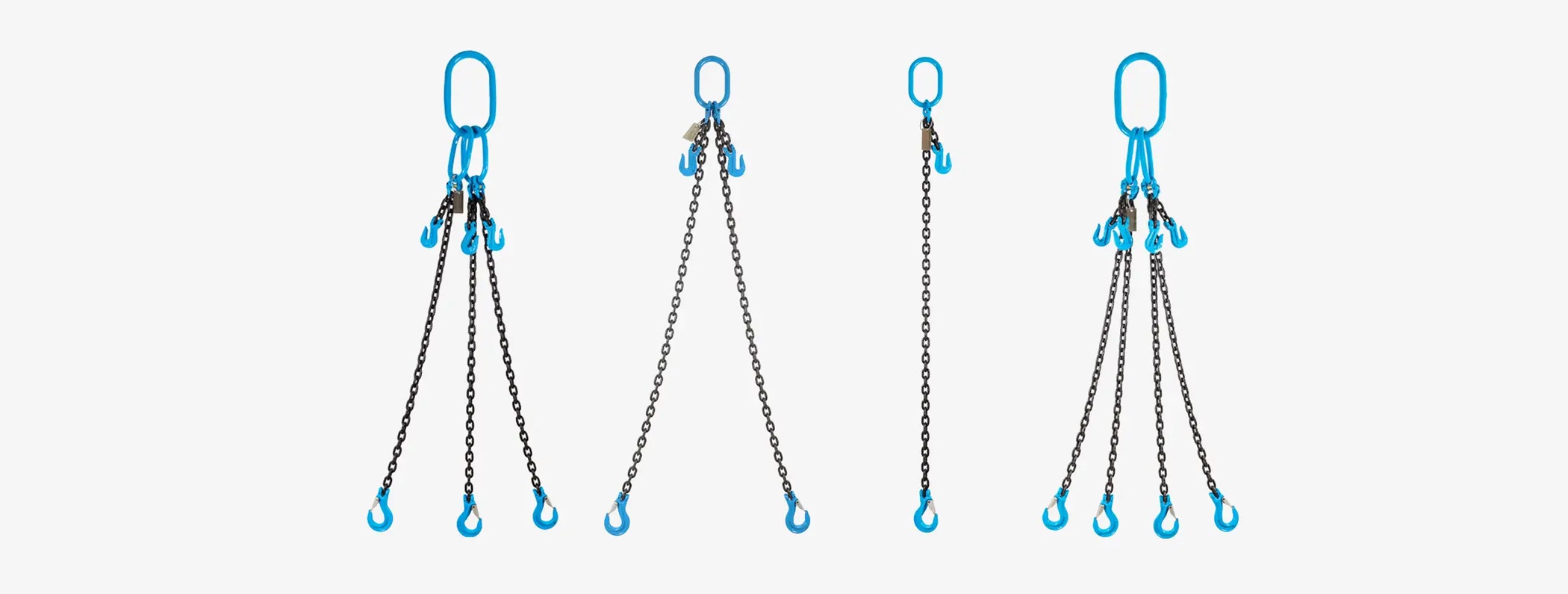

Wire rope slings are designed for lifting heavy loads. A wire rope machine twists multiple steel wire strands into a rope, providing strength while maintaining flexibility. When manufactured into slings, wire rope becomes one of the most commonly used styles for lifting applications. Unlike chain slings that handle heavier weights or synthetic slings that protect delicate surfaces, wire rope/steel lifting slings offer a balanced option for various lifting needs.

How They’re Made and Types Available

The production of wire rope rigging slings involves flemishing and swaging eyes of steel wires to form a rope. A core made of metal is placed in the center to add stability and help maintain the sling’s shape when carrying heavy loads.

Two common types of wire rope construction are:

- 6x19 Construction: This type consists of six strands, each containing 19 wires. It is known for its balance between strength and flexibility, making it useful for various lifting applications.

- 6x36 Construction: This variation has six strands, each containing 36 wires. The increased number of wires provides greater flexibility, making it a good choice for applications requiring more movement and bending.

When selecting a wire rope sling, construction type plays a role in how well it functions for specific lifting needs. For instance, handling loads with irregular shapes may be easier with a 6x36 construction because of its increased pliability.

Load Capacities: What You Need to Know

Understanding load capacity is critical when using wire rope hoisting slings. Each rigging sling is rated for specific weight limits based on its diameter and construction. Below is a general guide to safe working loads (SWL) for a 6x19 fiber-core wire rope sling:

| Diameter (inches) | Safe Load (lbs) |

|---|---|

| 1/4 | 1,100 |

| 3/8 | 2,400 |

| 1/2 | 4,400 |

| 3/4 | 9,520 |

For example, a 1/2-inch wire rope sling can lift up to 4,400 lbs, making it more than enough for most residential and light industrial tasks. Before lifting any load, always verify its weight and confirm that your sling is rated to handle it.

Pros and Cons: The Strengths and Limitations

Like any lifting equipment, wire rope slings have benefits and drawbacks.

Advantages

- High-Load Capacity: Wire rope slings are made for lifting heavy objects and are a common choice in industries that require dependable lifting solutions.

- Long Service Life: With proper care, these lifting slings last long, even in demanding environments.

- Adaptability: Useful in various industries, including construction, shipping, and manufacturing.

Disadvantages

- Weight: Heavier than synthetic slings, handling them is less convenient in some situations.

- Corrosion Risk: Exposure to moisture can cause rust over time if not appropriately maintained.

- Less Gentle on Delicate Loads: While flexible, Steel rope slings do not provide the same surface protection as synthetic slings.

A wire rope sling functions like a heavy-duty pickup truck—strong, dependable, and capable of handling tough jobs. However, regular maintenance is necessary to keep it in top condition. If you need something with even greater lifting power, chain slings are an option, while synthetic slings are better suited for applications requiring a softer touch.

Where They Shine: Real-World Applications

- Construction: Lifting beams, concrete panels, and other heavy materials.

- Shipping: Loading and unloading cargo.

- Logging: Moving logs and timber in outdoor environments.

- Industrial Work: Transporting machinery and materials in factories.

Outside of professional settings, wire rope slings can help move heavy furniture, secure large items during transport, or handle home improvement projects. Their ability to support heavy loads makes them practical tools for both business and personal use.

How Wire Rope Slings Compare to Other Lifting Options

Wire rope slings are a compromise between chain and synthetic slings. Chain slings are known for their heavy load-bearing ability, while synthetic slings are lightweight and easier to handle. Wire rope slings balance strength and adaptability, making them a practical choice for many lifting needs.

Understanding the differences can help you select the best sling for your project. If your job requires even greater strength, check out our guide on chain slings. Synthetic slings might be better if you need a softer option for delicate loads.

Safety and Maintenance: Tips for Longevity

Taking care of wire rope slings is important for safe and effective lifting. Here are some key maintenance tips:

- Inspect Before Use: Check for broken wires, kinks, or rust. If more than six wires in a strand are broken, replace the sling.

- Store Properly: Keep the sling in a dry place to prevent moisture damage.

- Apply Lubrication: Reduce friction and prevent rust by regularly applying lubricant.

- Handle With Care: Avoid dragging the sling on rough surfaces to prevent wear.

Following these steps helps maintain the sling’s strength and prevents unexpected failures during lifting operations.

Practical Insights from Real-World Use

Consider a construction crew lifting a steel beam into place. An adequately rated wire rope hoisting sling can handle the job while adjusting to different angles. These slings allow lifting and moving of heavy logs, even on rough terrain.

Steel wire rope slings can be just as useful for homeowners or DIYers. Whether moving heavy stones for landscaping or securing large items for transport, using the right lifting wire sling makes lifting safer and more manageable.

Final Thoughts

Wire rope slings are a practical choice for lifting applications in multiple industries. Their steel construction allows them to handle heavy loads while offering enough flexibility for various uses. By knowing the different construction types, load capacities, and maintenance practices, you can make informed decisions when selecting lifting equipment.

Every lifting job has different requirements. Chain slings might be a better option if your work involves extremely heavy loads, while synthetic slings could be better when handling delicate materials. Our in-depth guides on these alternatives can help you make the best choice for your needs.

With proper handling and upkeep, wire rope slings remain reliable tools for lifting operations. Whether on a job site or handling a project at home, using the right equipment makes all the difference. Happy lifting!